Motor performance began to decline and we need to be aware of the weight pull. Moreover, if we had regular servicing and fuel quality. There might be a part of the engine starting wear. Usually problems arise around the piston. When the piston remains problematic and the motor driven, will be very dangerous. Possibility cylinder injured and in extreme cases broken piston head is very large. In fact, the motor suddenly stopped and the rider was thrown when his spur in high speed. The result was fatal. Therefore, be aware of the symptoms of the problem in the piston is very important. As with any of these symptoms? How do I fix this? Here are his tips.

1 thick white smoke billowing from the exhaust

A piston is problematic symptoms and can be observed by naked eyes is the appearance of thick white smoke from the exhaust. This could happen because the piston has been rocking so when pushing the piston head to spray fuel into the engine combustion chamber there is a gap for oil to flow into the combustion chamber.

Oil that lubricates the piston to move back and forth it actually has been limited by the piston oil ring. However, due to worn piston rings and piston problem causing oil to seep into the engine combustion chamber. Lubricant was mixed with fuel and burned in the engine when the combustion process takes place. As a result, any smoke gushed along with combustion gases from the exhaust.

Piston broken apart due to age factor is also due to the treatment of the motor is damaged. Too heavy a load capacity exceeding standards, bulldoze extreme road continuously for a long time until installation errors, a few causes. The fix, of course, have to replace it.

2 Electric motors decreased dramatically

Another symptom is damage piston motor power suddenly becomes sluggish. This could happen because the piston-from handlebars, rings, and piston-head is not functioning optimally in pushing fuel into the combustion chamber. Strong pressure should not happen. As a result, the compression engine also dropped dramatically. As a result, the combustion process between the fuel and oxygen or air in the combustion chamber is not perfect. So that the power generated is also small.

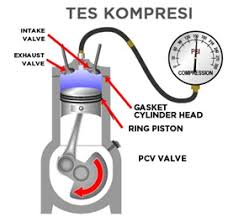

The cause of the piston that is not capable of providing the strong pressure as mentioned above. Improper installation, use the age factor, up to a motor that is too often haul heavy loads exceed the capacity of a standard. The fix is the same, the need to replace components. However, before replacing it make sure to do a compression test first in workshop that has such equipment.

1 thick white smoke billowing from the exhaust

A piston is problematic symptoms and can be observed by naked eyes is the appearance of thick white smoke from the exhaust. This could happen because the piston has been rocking so when pushing the piston head to spray fuel into the engine combustion chamber there is a gap for oil to flow into the combustion chamber.

| White smoke from oil entering the combustion chamber |

Piston broken apart due to age factor is also due to the treatment of the motor is damaged. Too heavy a load capacity exceeding standards, bulldoze extreme road continuously for a long time until installation errors, a few causes. The fix, of course, have to replace it.

2 Electric motors decreased dramatically

Another symptom is damage piston motor power suddenly becomes sluggish. This could happen because the piston-from handlebars, rings, and piston-head is not functioning optimally in pushing fuel into the combustion chamber. Strong pressure should not happen. As a result, the compression engine also dropped dramatically. As a result, the combustion process between the fuel and oxygen or air in the combustion chamber is not perfect. So that the power generated is also small.

The cause of the piston that is not capable of providing the strong pressure as mentioned above. Improper installation, use the age factor, up to a motor that is too often haul heavy loads exceed the capacity of a standard. The fix is the same, the need to replace components. However, before replacing it make sure to do a compression test first in workshop that has such equipment.